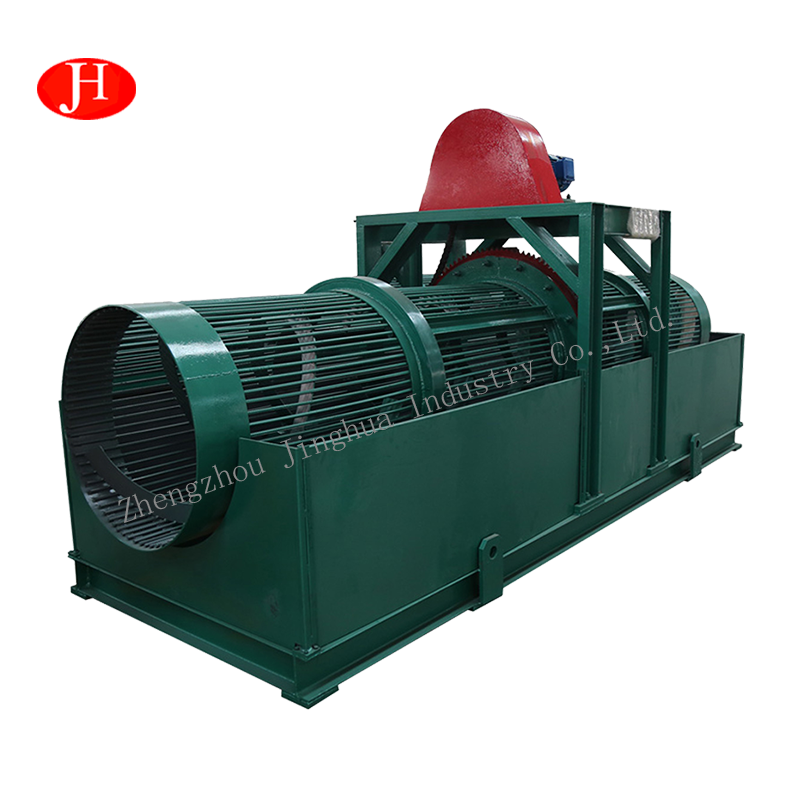

Pipe Bundle Dryer

Keywords:

Pipe Bundle Dryer

Projects

ABOUT US

Company Display

360 Degree Company Display

Features

01Using the principle of heat conduction and radiation, the material is transported into the dryer by spiral.

02The direction of steam is opposite to that of material,energy saving effect is good

03Large processing capacity, low power configuration, stable operation, easy installation and maintenance.

04Conducive to energy saving.

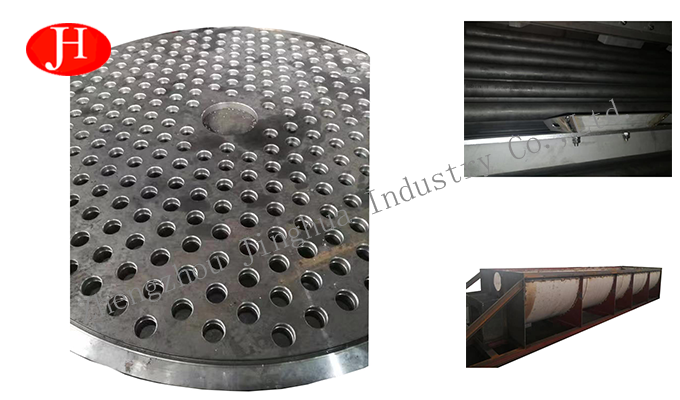

Product Details

Product details showcase quality

Using the principle of heat conduction and radiation, the material is conveyed into the dryer by a screw Driven by the agitation of the rotating tube bundle lifting plate, it moves from the feed end to the discharge end Heat absorption and water loss are completed during .

The movement, and the dryer is in a negative pressure state during production The direction of the steam is opposite to that of the material, and the energy saving effect is good.

Main Technical Parameters

|

Materials |

Germ |

Corn fiber |

Corn protein |

|

Inlet water content |

55% |

60% |

45% |

|

Outlet water content |

3~5% |

10~12% |

12~13% |

|

Drying intensity (evaporation kg water/ m2) |

2.5~3 |

4.8 |

4.7 |

|

Model |

Outline dimension |

power(kw) |

Weight (T) |

|

GZG60 |

6100*1600*2160 |

5.5 |

9 |

|

GZG100 |

7800*1900*2460 |

7.5 |

13.5 |

|

GZG150 |

7100*2200*2750 |

11 |

19.5 |

|

GZG300 |

8800*2460*3180 |

18.5 |

26.5 |

|

GZG500 |

10980*2900*4000 |

37 |

50 |

|

GZG650 |

11190*3200*4300 |

55 |

67 |

|

GZG1000 |

11800*3660*4770 |

110 |

91 |

Application Scope

Pipe bundle dryer is widely used in starch industry for drying germ, fiber, gluten. It is widely used in corn production line.

Send Inquiry

Leave a message immediately and receive free product consultation. We will arrange experts to contact you as soon as possible.