Airflow Drying

Keywords:

Airflow Drying

Projects

ABOUT US

Company Display

360 Degree Company Display

Features

01Fully considered each factor of turbulent flow, cyclone separating and heat exchange.

02Parts contact with starch is made of stainless steel 304.

03Energy saving, moisture of product stable.

04The moisture of starch is very stable, and varied 12.5%-13.5% by automatic control which can control the moisture of starch by controlling feeding quantity of steam and wet starch.

05Less starch loss from wind exhausted.

06The complete solved plan for a whole flash dryer system.

Product Details

Product details showcase quality

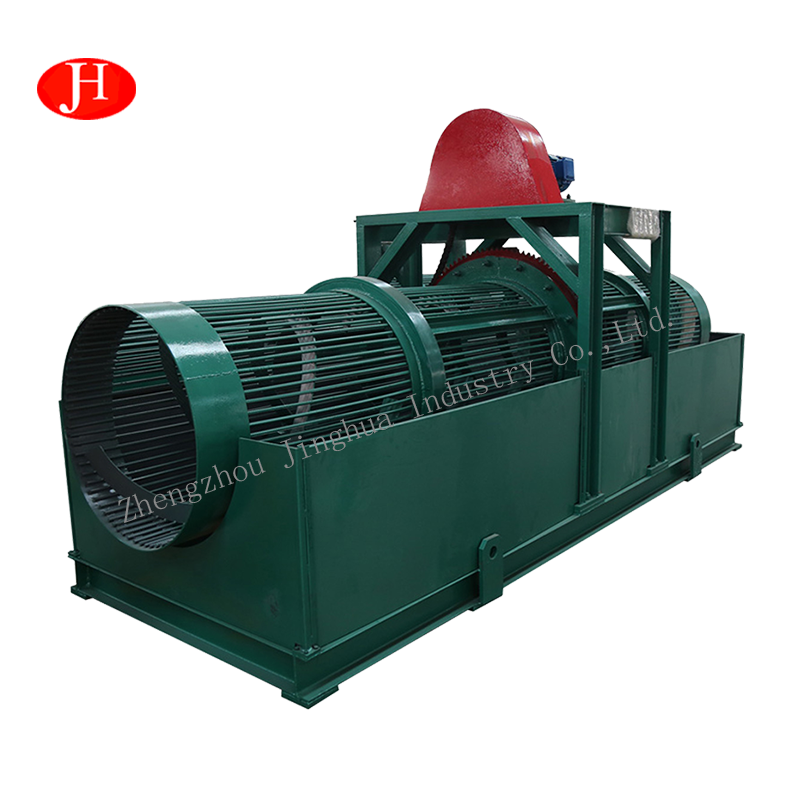

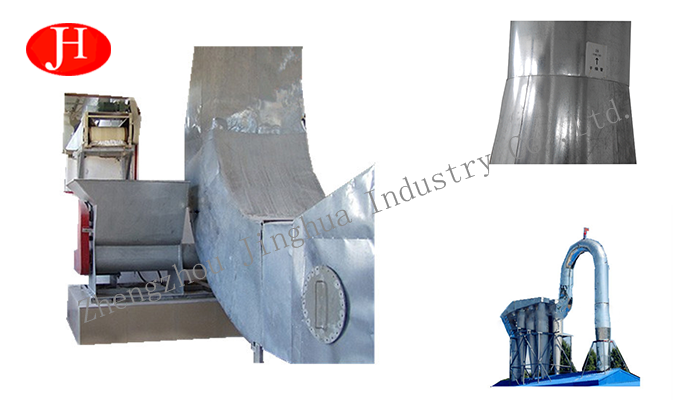

The cold air enters the radiator plate through the air filter, and the hot air flow after heating enters the dry air pipe. Meanwhile, the wet material enters the hopper of the feeding unit from the wet starch inlet, and is transported into the hoist by the feeding winch.The hoist rotates at high speed to drop the wet material into the dry duct, so that the wet material is suspended in the high speed hot air stream and heat is exchanged.

After the material is dried, it enters the cyclone separator with the airflow, and the separated dry material is discharged by wind winding, and the finished product is screened and packed into the warehouse. And the separated exhaust gas, by the exhaust fan into the exhaust gas duct, into the atmosphere.

Main Technical Parameters

|

Model |

DG-3.2 |

DG-4.0 |

DG-6.0 |

DG-10.0 |

|

Output(t/h) |

3.2 |

4.0 |

6.0 |

10.0 |

|

Power capacity(Kw) |

97 |

139 |

166 |

269 |

|

Moisture of wet starch(%) |

≤40 |

≤40 |

≤40 |

≤40 |

|

Moisture of dry starch(%) |

12-14 |

12-14 |

12-14 |

12-14 |

Application Scope

Mainly used for canna starch, sweet potato starch, Cassava starch, potato starch, wheat starch, corn starch, pea starch and other starch production enterprises.

Send Inquiry

Leave a message immediately and receive free product consultation. We will arrange experts to contact you as soon as possible.